SKU:Product Code: 928601

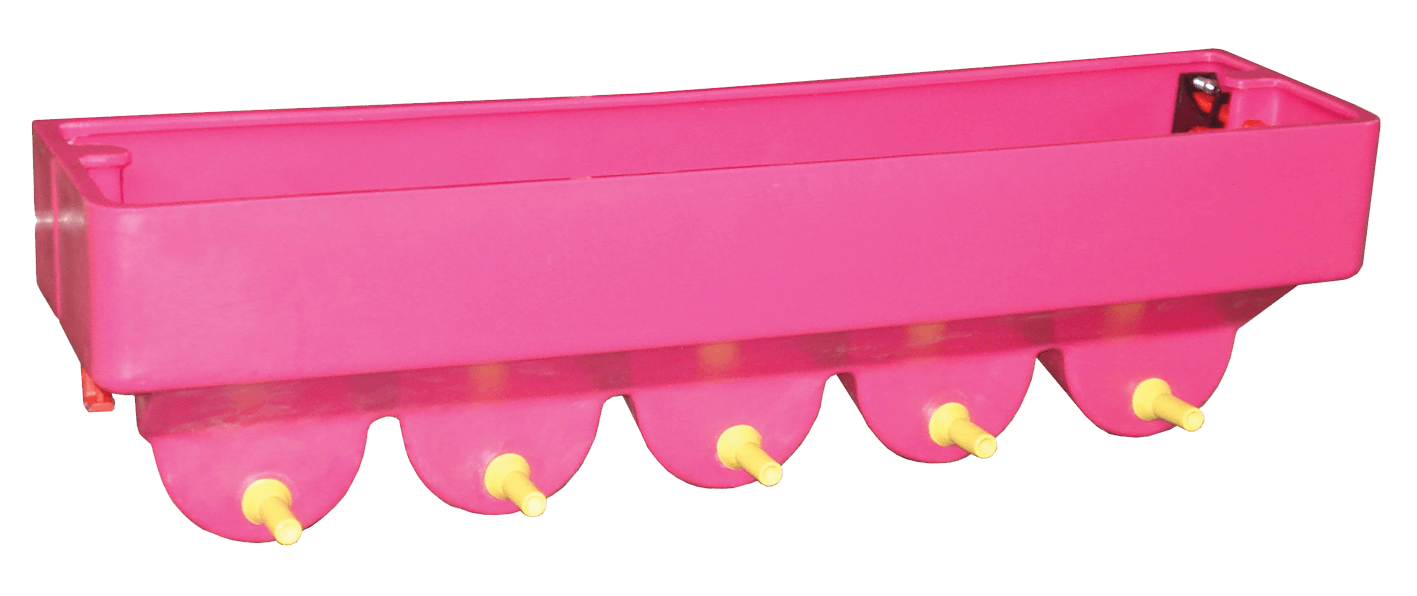

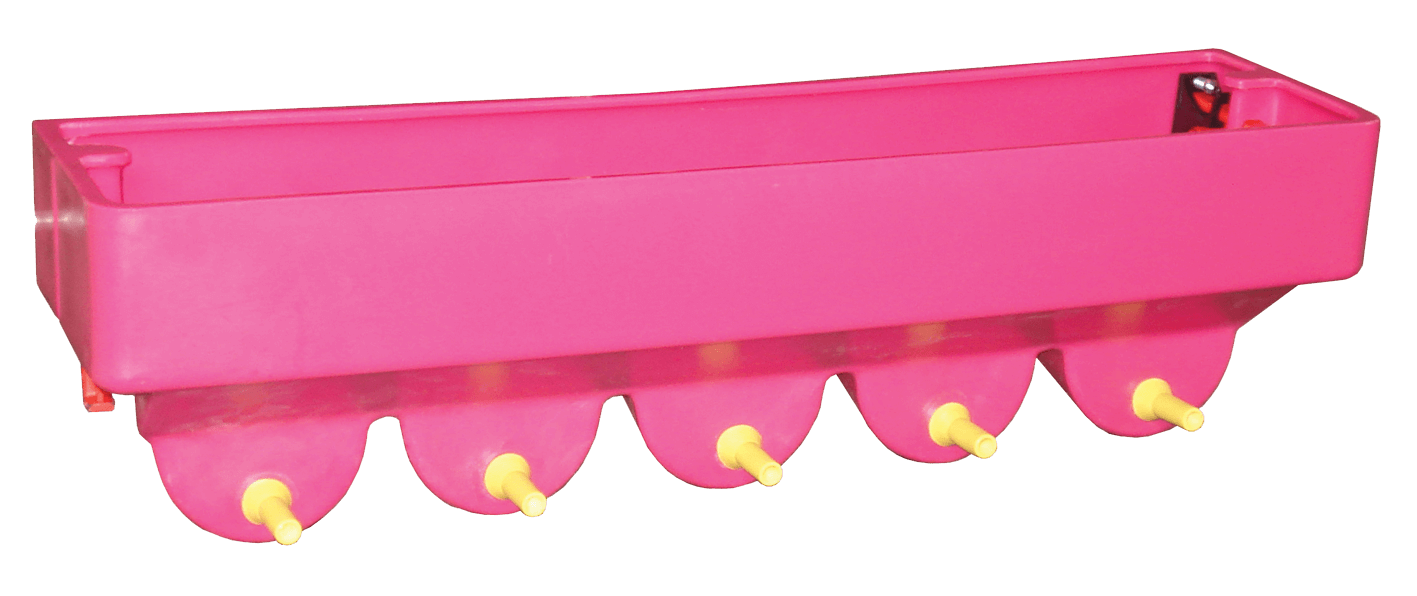

Milk Bar™ Lamb/Kid 5 Compartment - Training Teat

Milk Bar™ Lamb/Kid 5 Compartment - Training Teat

Fitted with Milk Bar™ Lamb/ Kid Training Teats, the compartments let you monitor the feeding speed so you can rearrange groups if you need to.

Well shaped compartments are easy to clean.

A great training feeder.

How to use

How to use

With Ezi Lock Hooks you can hang this feeder on anything from wooden rails to steel gates.

Simply hang the feeder in place, lock the hooks and fill with milk.

After feeding you can either remove the feeder, or flip it upside down until the next feed.

To give your lambs and kids the best drinking position, hang the feeder on a rail around 50 cm high. This puts the teat at 25cm which is the optimum height for them and helps the oesophageal groove to close and milk to bypass the rumen.

How do I change my teats?

Milk Bar™ Teats have a pull through design to sit snugly against the feeder wall for optimum hygiene. However, while this is the most hygienic system, it can also be difficult to change teats!

Use a Teat Tool: This is by far the easiest method. The purpose designed Teat Tool plucks the teat from the feeder with minimal effort in seconds.

Pull the teats out by hand: When removing by hand, make sure to either pull the teat directly down or up. If you try to pull the teat straight out, it will be a tough job!

Cut the teats out: Make sure the blade is sharp and you use the knife away from you.

Be sure to check the teat alignment is correct and the slit is vertical!

Cleaning

Cleaning

Milk is a difficult substance to clean off of surfaces. You need hot water to remove the fat, but the heat can bake the protein onto the surface. Using warm water to get rid of the protein leaves a film of fat. When fats and proteins stick to the surface of equipment, they form a biofilm, a nutrient-rich layer in which bacteria grow.

The biofilm protects bacteria from the cleaning process and results in equipment that appears clean but has bacteria on the surface. The cleaning process not only needs to remove fat and protein from surfaces but prevent the formation of a biofilm.

Made from renewable, high quality natural rubber, Milk Bar™ Teats are kinder to the environment. Natural rubber absorbs the milk fat and protein which can cause the teats to become softer and start to drip. The milk flow can become faster, decreasing calf performance.

Recommended cleaning: Use Milk Bar™ Detergent, a dishwashing detergent, or any other non-chlorine/ chloride dairy detergent twice a week. Important! Chlorine/chloride based dairy detergents degrade natural rubber which reduces teat performance and voids any warranty.

Rinse your teats with water.

Use a gentle detergent, following the manufacturer’s instructions. Do not use Chlorine/chloride based dairy detergents!

Using a brush, lightly scrub the outside of the teats making sure to bend the teats. By bending the teats, any milk gets pushed back inside the feeder so the detergent can make contact with the inside of the teat wall.

Rinse clean.

1. Rinse your teats with water.

2. Use a gentle detergent, following the manufacturer’s instructions. Do not use Chlorine/chloride based dairy detergents!

3. Using a brush, lightly scrub the outside of the teats making sure to bend the teats. By bending the teats, any milk gets pushed back inside the feeder so the detergent can make contact with the inside of the teat wall.

4. Rinse clean.

FAQs

FAQs

The Milk Bar™ Lamb/ Kid 5 Compartment with Training Teats comes with the teats and hooks fitted and ready to use.

Volume: 300ml per compartment

Weight: 2kg

Length: 680mm

Height: 180mm

Width: 170mm

Warranty: The feeder has a two year warranty with proof of purchase.

The warranty does not apply to consumable parts (teats and hooks).

Made from food grade polyethylene and U.V Stabilised for long life.

Milk Bar™ Teats are made from a natural rubber with no synthetic or oil based rubber.

NZ Pat Apps 757655 & 767633 PCT Patent Application NZ2020/050110 International Patents pending. NZ Pat 518590 NZ Des Reg. 420972 NZ Pat 247112